The 45-Second Trick For 24??media

The 45-Second Trick For 24??media

Blog Article

The Basic Principles Of 24??media

Table of ContentsThings about 24??mediaGetting The 24??media To WorkAll About 24??mediaUnknown Facts About 24??mediaGetting The 24??media To Work

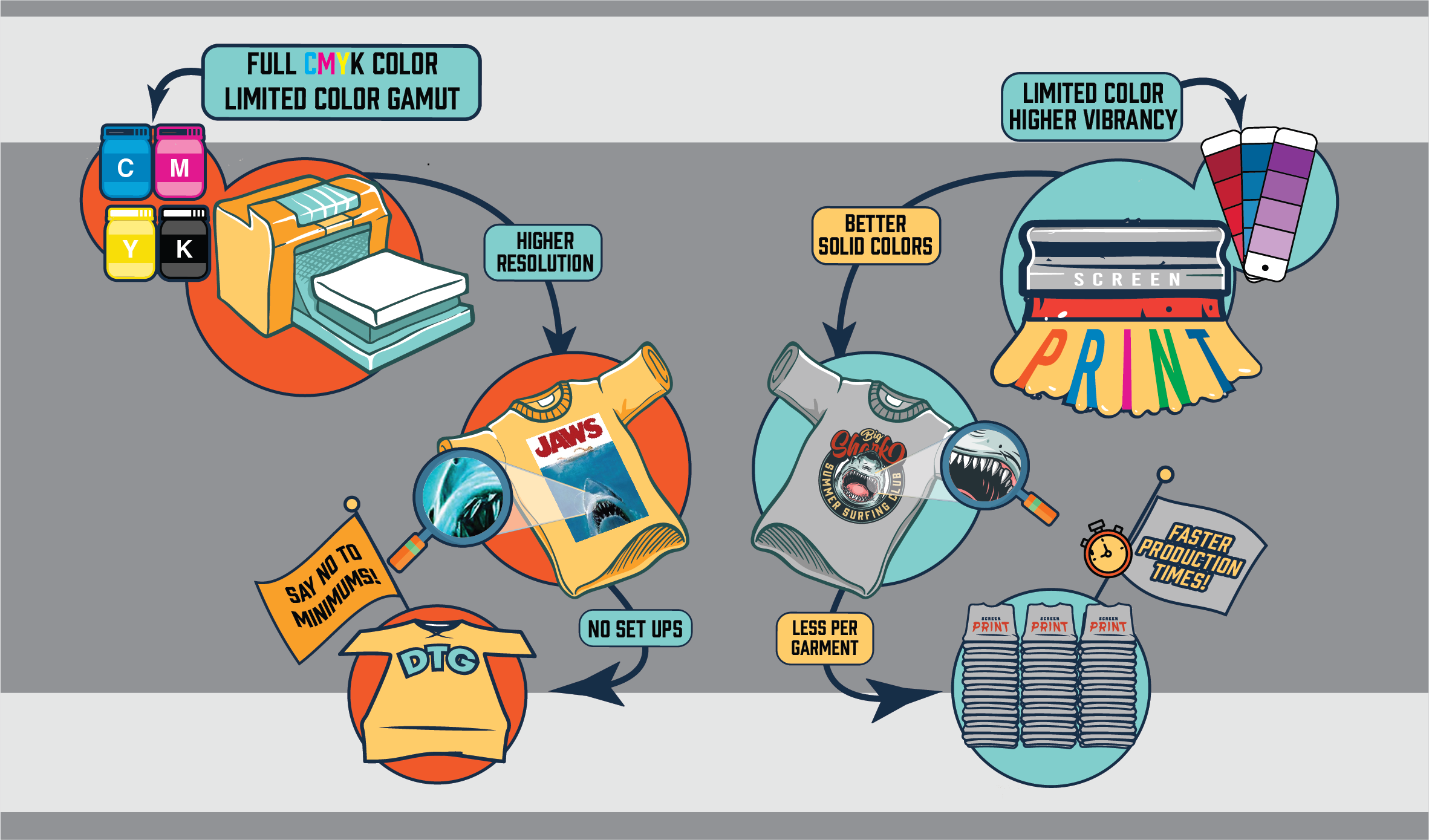

Innovations in print innovation are altering the communications playing field when it pertains to high quality, affordability and cutting-edge capacities. Countered printing and digital printing are the major processes through which print tasks are undertaken both making use of four-color printing techniques. Each alternative has its advantages, supplying different methods to meet the demands of varied production tasks.

Normally, this has been the most constant method for precisely maintaining color matches, making it suitable for print runs that just require static printing such as pre-printed types, pamphlets, leaflets, company cards, and bulk postcard mailings. However, due to the static nature of litho printing, it is not optimal for variable print pieces that will be mailed to individual receivers such as declarations, letters, and individualized postcards.

About 24??media

The newest advancements in print technology are aiding to bring many of balanced out's advantages into the electronic printing globe really transforming the face of modern-day printing! There are some key distinctions in between Offset Printing and Digital Printing.

Today's electronic print tools is among the most innovative on the market. Below are several of the most significant benefits of using digital printing: control the electronic print room, with full-color printing finished in one procedure and perfectly printed directly from a print file. Without a prolonged set-up process, the calibration time of a particular job is shortened, adding to quicker print time and overall delivery.

The inkjet printing procedure has actually assisted to transform the market along with the high quality and speed of the outcome. The most current inkjet innovation can publish on traditional countered supplies with dull, silk, and shiny coatings. High-quality electronic print coupled with software-managed shade management techniques adds optimum worth to print items and makes manufacturing processes much more dependable than balanced out.

3 Easy Facts About 24??media Explained

(https://za24media.creator-spring.com/)

Environmentally friendly and naturally degradable inks and printer toners are additionally available for more sustainable printing. Digital print additionally removes the requirement to clean plates or coverings with dangerous chemicals at the end of the printing procedure.

Variable data aids businesses reach their exact customers and target market with uniquely-created and customized web content. As technology boosts, the high quality of digital printing has become second-to-none, with better detail, color suit capabilities and total accuracy. Without the requirement to wash plates or utilize excess ink, digital printing is also much less inefficient and generally more eco-friendly.

("flexo"), include multiple make-ready actions to move an original image to a substratum.

Little Known Questions About 24??media.

Digital printing, with less relocating pieces, is a lot more dexterous than balanced out in this respect.

It's a way to blend your packaging and check my reference advertising and marketing techniques. Lowered set-up time saves money on the front end. And since these are not large bulk orders, smaller sized organizations can manage to print without having to satisfy the higher and extra costly print limits of standard printing. Digital printing helps protect your brand versus counterfeiting by integrating obvious and covert solutions on your packaging.

Make sure you work together with a printing and packaging partner that has the appropriate certifications. While eleventh-hour printing and customization are a big advantage, digital may not constantly be the best technique for you. For example, offset printing has the benefit of cost-effectiveness with big print runs, especially those with advanced attractive impacts and specialty layers.

Indicators on 24??media You Need To Know

Lithographic presses use two print platesa favorable and a negativeto transfer premium shade graphics onto an appropriate substratum. The positive plate, with its smooth surface, brings in oil-based inks and pushes back water. On the other hand, the negative plate, with its harsh texture, takes in water and drives away oil. Rubber rollers are then made use of to transfer the picture from home plate to the corrugated surface.

Corrugated paper can in some cases verify to be a challenging surface to print on, however Litho prints to a separate surface and is then laminated to it, making it easy to print high-quality images. It can be extremely consistent, even for long terms. Actually, the more you print, the more affordable the prices come to be for Litho.

If you have enough time and budget, and a big volume of a single layout, then there shouldn't be a concern. What Litho does not give you is exactly what Digital does, personalization. Much more on that particular later. Expensive established Longer turnaround No Variable Information Printing Smaller shade range, colors can be less intense Digital printing is the process of printing electronic photos straight onto the corrugated substratum utilizing a single-pass, direct-to-corrugate method - Window Vinyl.

Report this page